Home – Facilities

Facilities

Facility Overview

Innovative PCB Manufacturing and E&D Center

Unit - 1

Plot No. 86, HPSIDC, Industrial Area, Baddi Distt. Solan, Himachal Pradesh, India 173205

Capacity: 2, 50, 000 Sq mtr/Annum

Unit - 2

Plot No. 7, DIC Industrial Area, Baddi Distt. Solan, Himachal Pradesh, India, 173205

Capacity: 2, 40, 000 Sq mtr/Annum

Unit - 3 (Upcoming Unit)

Upcoming flagship facility in Jammu & Kashmir

Capacity: 3, 60, 000 Sq mtr/Annum

Research & Process

Design and Prototyping : The journey begins with a comprehensive PCB design. Using advanced CAD tools, our design team works closely with clients to create custom layouts based on specific project requirements.

PCB Material Selection : Choosing the right materials is critical to ensure performance and durability. Depending on the project needs, we select from a range of high-quality materials such as FR4.

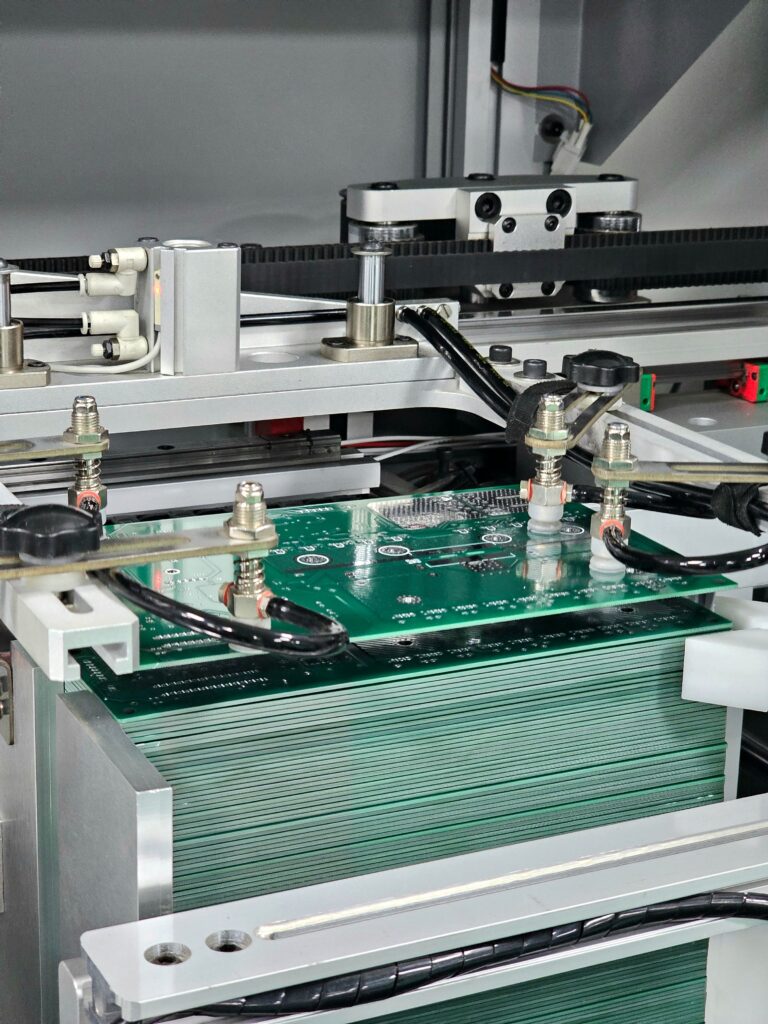

Cutting and Drilling : Next, drilling of vias (small holes) is performed to create electrical connections between layers. These drilled holes are then plated with copper to ensure proper conductivity between layers.

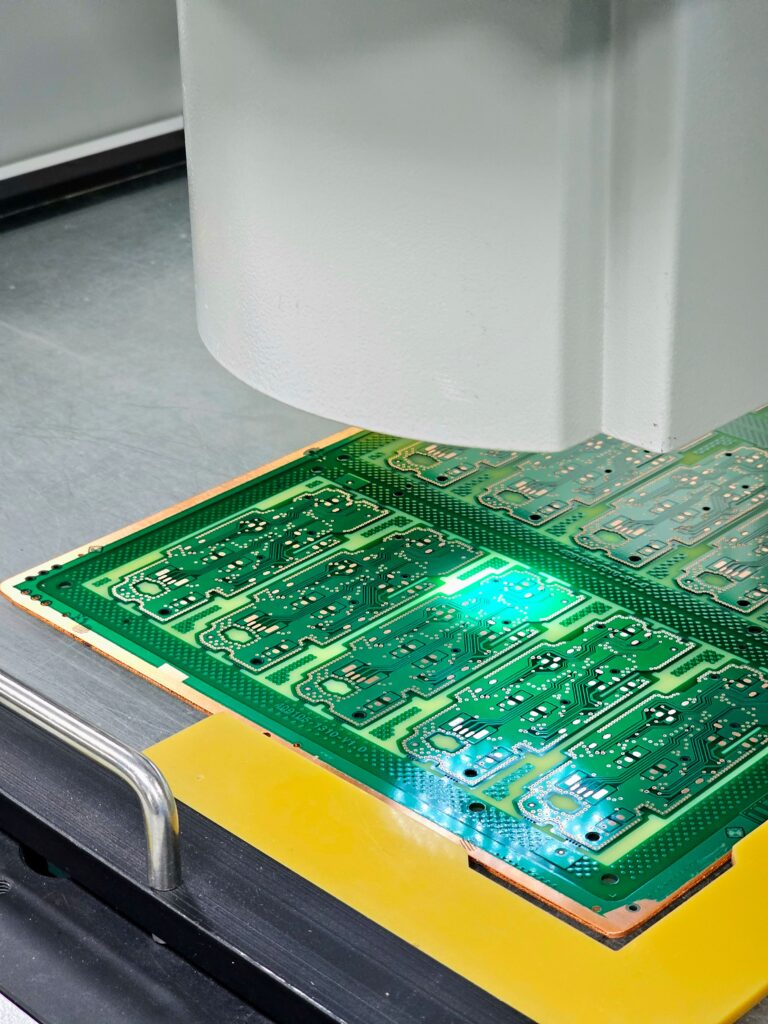

Photolithography & Plating : Photolithography is a precise and widely used technique in the semiconductor and microfabrication industries to pattern designs on substrates. This process plays a pivotal role in creating printed circuit boards (PCB).

Micro Section & Etching : Micro-sectioning and Automated Optical Inspection (AOI) are critical post-etching quality control steps in PCB (Printed Circuit Board) manufacturing & checked different defects like PTH thickness, Line width violations, spacing violations, excess copper, short or open circuits, etc.

Solder Mask and Developing : A solder mask is applied over the etched copper surface of a printed circuit board (PCB) to protect it from environmental contaminants and oxidation. This protective layer also helps define the areas where components will be soldered by preventing solder bridges between closely spaced pads.

Surface Finish : Lead-Free HASL, OSP, Immersion Gold, and Immersion Tin are common PCB surface finishes, each with unique properties and applications.

Quality Testing : To ensure and validate product quality, various tests are performed, including Electrical Testing, Solderability Testing, Hole Checking, Automated Visual Inspection (AVI), and profile verification using a (VMS)

Packaging and Delivery : The final product is vacuum-packed with silica dioxide and securely enclosed in robust corrugated boxes to safeguard against environmental factors. We ensure safe packaging and collaborate with trusted shipping partners to guarantee timely and secure delivery to your location.