Production Capacity :- 5000 sqm / month

Sector Catered : Automotive, Lighting, Industrial Electronics, Home Appliances, Railways, Power Electronics, Automation, Storage Devices, Solar Systems.

Production Capacity :- 5000 sqm / month

Sector Catered : Automotive, Lighting, Industrial Electronics, Home Appliances, Railways, Power Electronics, Automation, Storage Devices, Solar Systems.

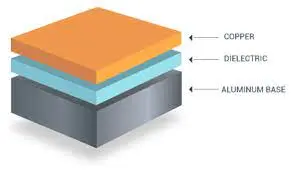

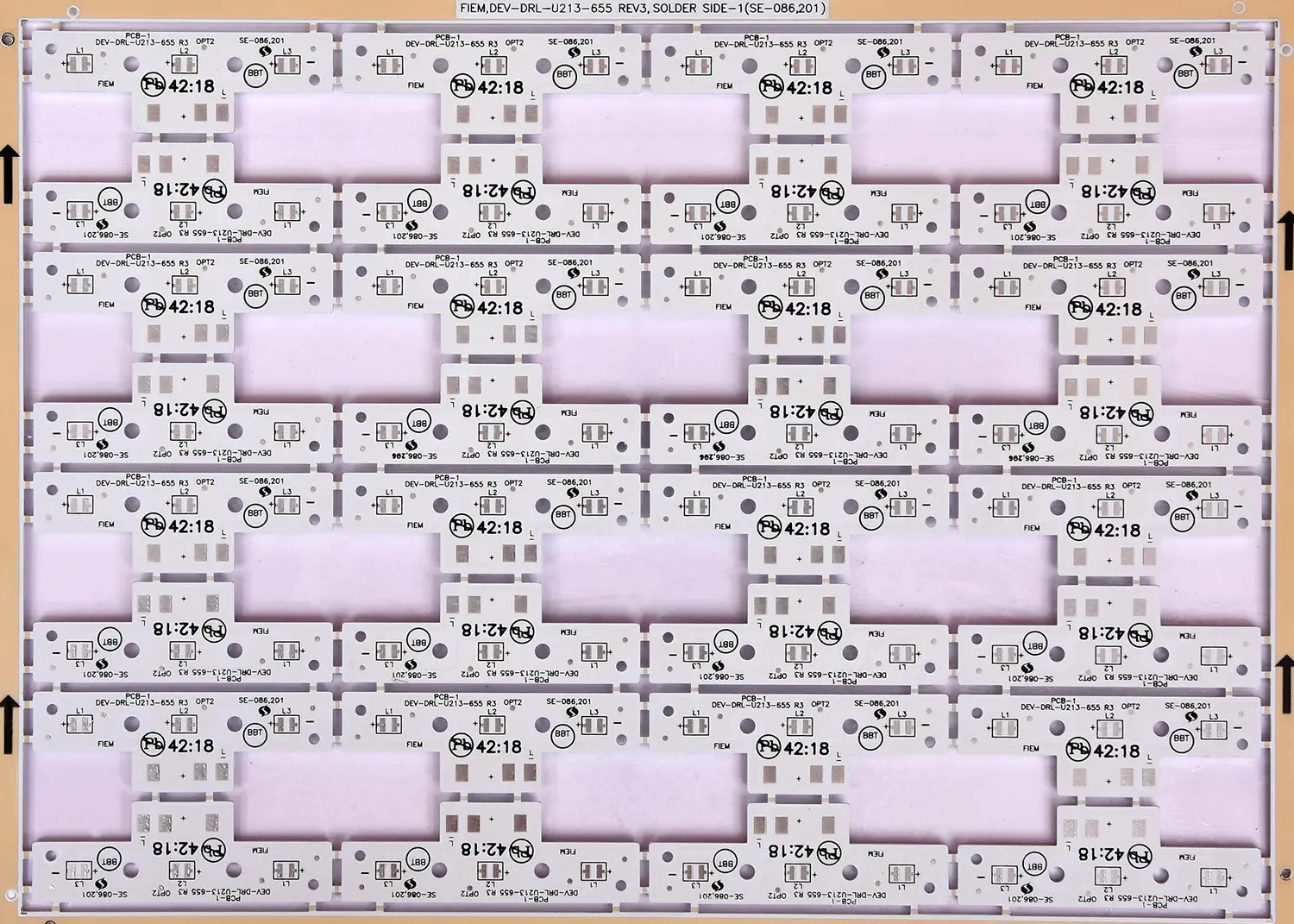

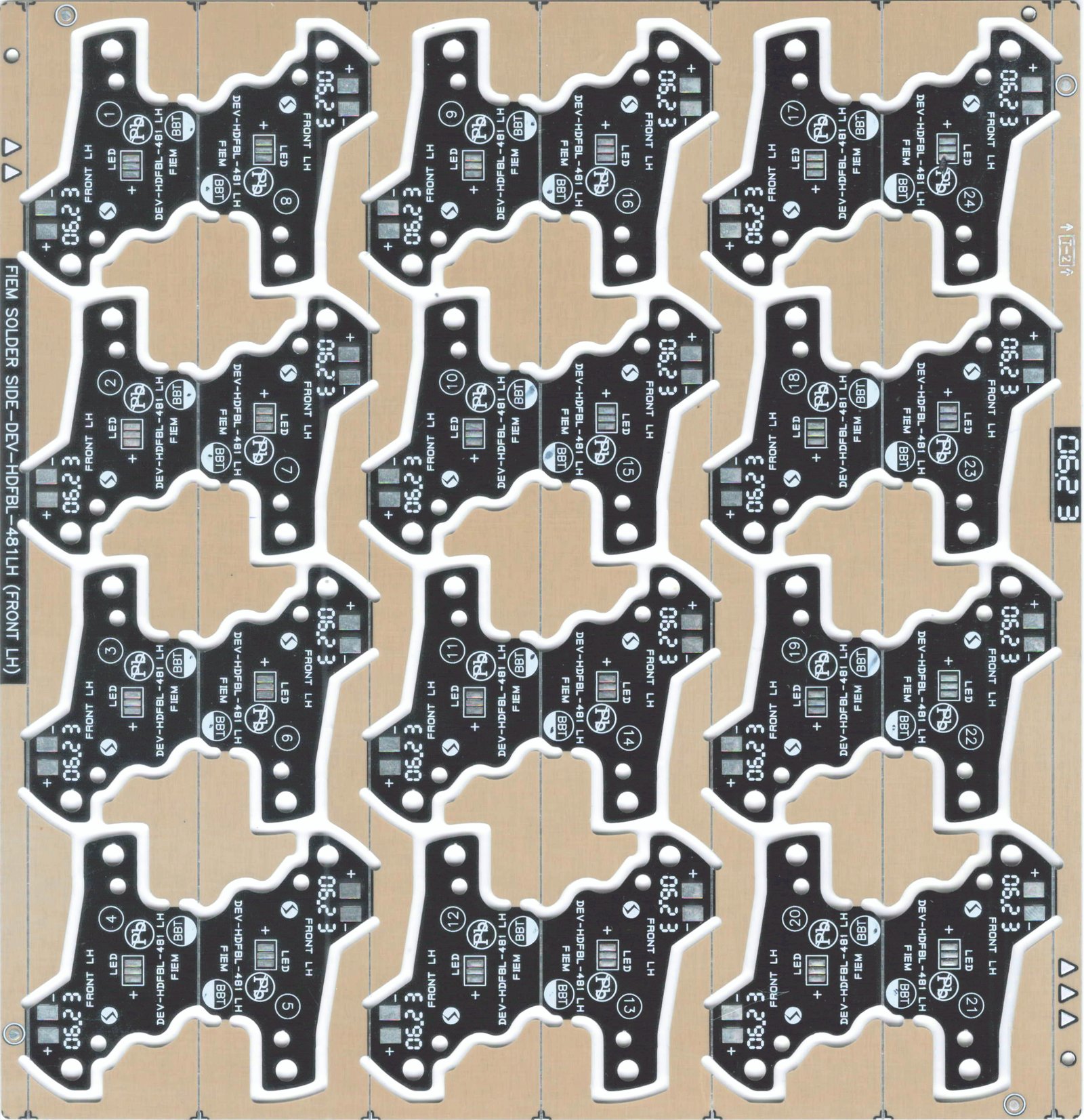

Metal Core Printed Circuit Boards (MCPCB) are specialized PCB designed to manage heat more efficiently than traditional PCB. They incorporate a metal core (usually aluminum, copper, or a mix of alloys) as their base material instead of the standard FR4 or epoxy resin. This metal core enhances thermal conductivity, making MCPCB ideal for heat generate during the use.

Superior Thermal Management : The metal core effectively dissipates heat away from components, preventing overheating and improving performance.Ideal for high-power applications such as LEDs and power electronics.

Enhanced Durability : Metal cores provide excellent mechanical strength, making MCPCB more resistant to vibration, shock, and bending.Suitable for rugged and industrial environments.

Improved Reliability : Reduced thermal stress on components increases their lifespan and ensures stable performance.Minimizes the risk of circuit failure due to overheating.

Compact Design : Efficient heat dissipation allows for higher component density and smaller overall designs.Enables the development of compact, high-performance devices.

Electrical Isolation with Thermal Conductivity : The insulating layer between the metal core and the conductive layer provides electrical isolation while maintaining excellent heat transfer.

Cost Efficiency for Heat-Sensitive Applications : By reducing the need for additional cooling systems (like heat sinks or fans), MCPCB can lower overall system costs.

Versatility : Compatible with a wide range of applications, including automotive lighting, power supplies, industrial machinery, and renewable energy systems.

Higher Cost : The use of metals like aluminum or copper increases the material cost compared to standard FR4 PCB.Manufacturing processes are more complex, leading to higher production costs.

Limited Design Flexibility : Metal cores make the PCB rigid, limiting the ability to create flexible or intricate designs.They are not suitable for applications requiring flexible circuits.

Complex Manufacturing Process : Drilling and etching processes are more challenging due to the metal core.Requires specialized equipment and expertise, increasing lead times.

Heavier Weight : The metal core adds significant weight compared to traditional PCB, which may be a concern for lightweight or portable applications.

Electrical Isolation Challenges : Additional effort is required to ensure proper electrical isolation between the metal core and the conductive layers, adding complexity to the design.

Limited Layer Count : Most MCPCB are single- or double-layer designs; achieving multilayer designs with metal cores is more challenging and expensive.

Thermal Expansion Mismatch : Different thermal expansion coefficients between the metal core and other PCB materials can cause stress, leading to potential reliability issues.

© 2024 Signum Electrowave.All rights reserved.

© 2024 Signum. All rights reserved.

+91 8352002222

In a strategic move to strengthen our manufacturing capabilities and adopt cutting-edge technology, Team Signum recently completed a successful visit to China to explore and procure state-of-the-art equipment for our upcoming PCB production unit in Jammu.

The visit was part of our continuous commitment to innovation and excellence in the PCB industry. During the tour, our senior technical and operations team engaged with leading global manufacturers of PCB machinery and automation systems. The objective was to identify and integrate next-generation equipment that would enhance production efficiency, quality control, and scalability at our new facility.

In a strategic move to strengthen our manufacturing capabilities and adopt cutting-edge technology, Team Signum recently completed a successful visit to China to explore and procure state-of-the-art equipment for our upcoming PCB production unit in Jammu.

The visit was part of our continuous commitment to innovation and excellence in the PCB industry. During the tour, our senior technical and operations team engaged with leading global manufacturers of PCB machinery and automation systems. The objective was to identify and integrate next-generation equipment that would enhance production efficiency, quality control, and scalability at our new facility.

In a strategic move to strengthen our manufacturing capabilities and adopt cutting-edge technology, Team Signum recently completed a successful visit to China to explore and procure state-of-the-art equipment for our upcoming PCB production unit in Jammu.

The visit was part of our continuous commitment to innovation and excellence in the PCB industry. During the tour, our senior technical and operations team engaged with leading global manufacturers of PCB machinery and automation systems. The objective was to identify and integrate next-generation equipment that would enhance production efficiency, quality control, and scalability at our new facility.